Electronic Soldering Service

Precise and bespoke Soldering Solutions

Electronic soldering of is a fundamental service in the manufacturing and assembling of electronic devices. At CTA, we offer bespoke electronic soldering services catering to a broad range of industries requiring precision and reliability. Our team is equipped with state-of-the-art tools and extensive expertise in handling various electronic components. We understand the pivotal role that soldering quality plays in the functionality and longevity of electronic products. Therefore, we are committed to delivering soldering solutions that meet the highest standards of quality.

We cater to Clients who require the integration of electronic components, cables and small parts into their hardware. Our soldering processes are engineered to ensure strong, conductive joints, which are essential for the optimal performance of the final product. Our technicians are adept in both traditional and innovative soldering techniques, enabling us to tackle a diverse array of assembly challenges.

Our measure of success is in the satisfaction and trust of our Clients, which is why we emphasise transparency and meticulous attention to detail in every project. By choosing our electronic soldering service, our clients are assured of a dedicated Partner that provides tailored soldering solutions, in alignment with the specific needs of each project.

Essential Soldering Equipment and Materials

Our comprehensive electronic soldering services rely on an array of essential equipment and materials to ensure the highest quality for our clients' diverse requirements.

Lead-free tin

We utilise a variety of lead-free tins to meet any possible specifications. The selection between materials such as tin-copper-silver is guided by their melting points and mechanical properties. Furthermore, during soldering, we operate with very precise techniques that play a fundamental role, facilitating the bonding of the tin to the printed circuit pads, eliminating oxidation and impurities.

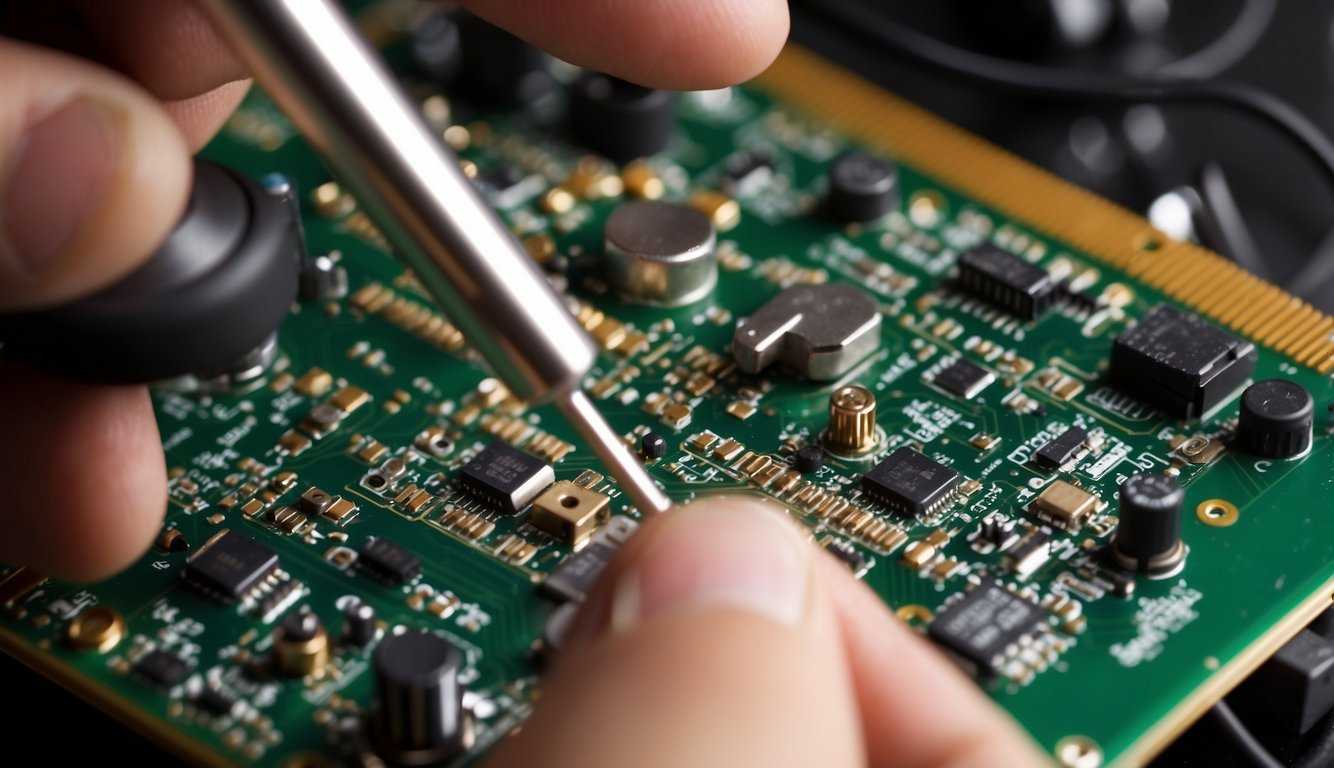

Our Soldering Irons, Stations and other Tools

Our soldering stations are equipped with high-quality soldering irons featuring precise temperature control, vital for consistent results. We safeguard the longevity and performance of our soldering tips through careful selection and maintenance, ensuring reliable hand soldering and rework capabilities.

Our toolkit also includes essential items such as tweezers, pliers, cutters, and desoldering pumps for efficient servicing of printed circuit boards.

Soldering Techniques and Quality Control

In delivering custom electronic soldering services, we at CTA employ stringent techniques and testing protocols to ensure the highest quality in our work.

Techniques for Precision and Reliability

We understand the importance of precision in hand soldering services, particularly when dealing with complex PCBs. Our skilled technicians utilise temperature control methods to ensure the solder is evenly distributed, reducing the risk of cold solder joints. We use:

- Fine-tip soldering irons to increase accuracy on small pads and components.

- Stereo microscopes to magnify work areas for intricate tasks.

- A steady hand technique in conjunction with machinery for a blend of precision and efficiency.

Quality Control and Testing Protocols

After soldering, each assembly undergoes a rigorous quality check. This includes:

- Visual Inspection: We closely inspect solder joints for consistency and proper wetting to the pad.

- Functional Testing: If functional testing is enabled, each unit gets tested under operating conditions to diagnose potential issues ahead of time.

FAQs on electronic soldering services

As a leading provider of bespoke electronic soldering services, we understand that the complexities of electronic soldering often give rise to numerous questions. In this section, we address some of the most frequently asked questions to help you make informed decisions.

What factors influence the cost of an electronic soldering service?

How do I select the best service provider for electronic soldering?

What qualifications should a professional soldering expert possess?

Would you like to receive special insights on industrial electronics?