Contract Electronics Manufacturing: Main Production Phases

produzione

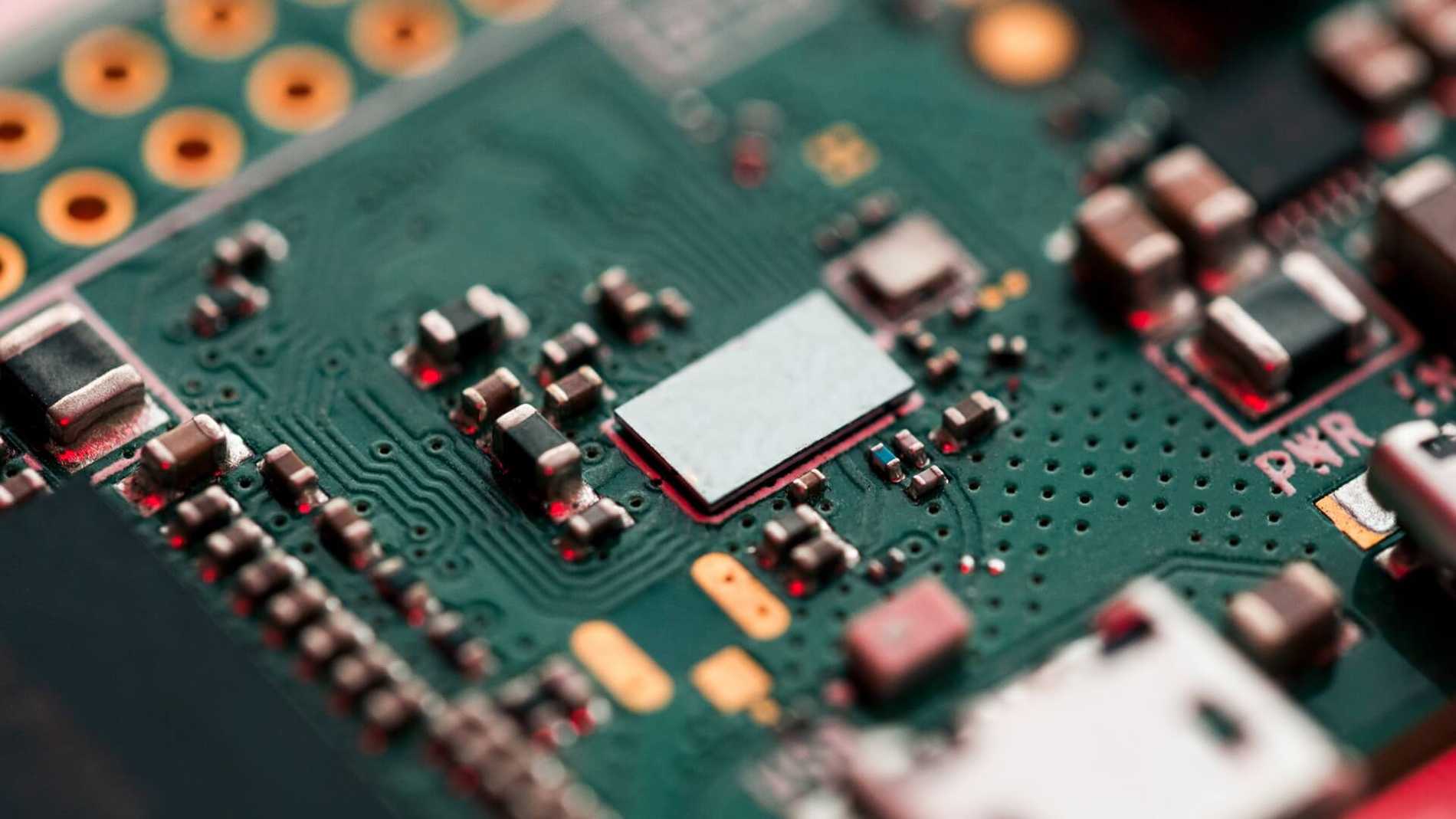

The production of electronic boards for third parties is one of the primary businesses of CTA Electronics and as such represents a segment studied, analyzed and treated down to the smallest detail. Generally, it takes place on order and consists of a chain of activities, closely interconnected, which must be performed with the utmost precision and at the right pace, to ensure an efficient and punctual workflow.

Guaranteeing the Customer an effective production system contributes to the quality of the final output to the same extent as the upstream electronic design and the choice of components.

An efficient work flow is regularly structured in phases following the process from the origin until its completion, which takes place with the activation of the outbound logistics and the delivery of the finished product to the Customer.

The production of electronic boards, engineered

The manufacturing planning aims to engineer the production, transforming it into a set of defined and highly optimized processes. Generally speaking, the phases that make up the production processes can expand or decrease according to the peculiarities of the individual batches and are structured to guarantee high quality and efficiency standards. All of them include the integration of documental and IT tools that allow constant traceability, a constantly updated document flow and direct control over the status of the processes.

In CTA Electronics, the basic organization of the production of electronic boards consists of the following phases.

First phase: evaluation of requirements of the production batches to be managed

The pillar of this phase is to make sure the batches are handled accordingly to any specific requirement, which can be backed up either by technical reasons or by Customer preference. In fact, before starting the actual production of the electronic boards, it is necessary to analyze this aspect so that the entire production order gets set up in the most appropriate and compliant way.

Second phase: activation of incoming logistics

The production of electronic boards in series requires not only an appropriate production capacity, but also an efficient logistics activity that guarantees the timely availability of the electronic components in use along the entire production path. Logistics and warehouse work in close synergy to feed industrial production by making the right inputs accessible according to a predefined schedule.

Third phase: pre-processing of materials and electronic components

In this phase we proceed to the set of activities that have the purpose of preparing the materials and electronic components for the actual assembly. In particular, among the most frequent pre-processing in a production flow of electronic boards we find:

- The overall preparation of the components

- The mechanical masking of partial areas of the printed circuit

- The assembly of materials that need a mechanical fix and need to be exempt from soldering

Fourth phase: start of the complete production process

The production process of a batch of electronic boards is divided into different phases, depending on the assembly technology used, which can be either SMT (Surface Mounting Technology) or THT (Through Hole Technology). The combination of the two is also very frequent: SMT productions are often followed by a completion in THT. An an example, THT processes are carried out on the basis of the following steps:

- The first step is the assembly of the components on the printed circuit;

- The second step consists of the soldering process, which can take place through the use of static pots managed by qualified operators or through wave soldering, depending on specific needs. All the materials used during the soldering process of the electronic boards comply with the current regulations in terms of non-toxicity and safety and the pots are exclusively lead-free;

- The third step consists of finishing processes that include cleaning;

- The fourth step concerns the tests and inspections aimed at verifying the quality of the production batch. For this purpose, electronic tools and visual inspections are used and combined by qualified personnel;

- The fifth step consists of accessory and complementary steps; among the most typical we find the completion with Conformal Coating, which consists in the application of special polymers to protect the components and the printed circuits.

Fifth phase: packaging and start of outbound logistics

In this phase, the production batch is organized within the most correct packaging, often composed of different layers of packaging. The outbound logistics then proceeds to the delivery according the Customer schedule. CTA Electronics is widely structured to guarantee maximum urgency deliveries carried out by its own operators or by specialized Partners.

For more information on the production of electronic boards and more generally on all the Contract Electronics Manufacturing services that CTA Electronics offers to its valued Customers, you can contact us at any time or visit specific areas of the website.

Would you like to receive special insights on industrial electronics?